NMRV-F

Technical Specifications

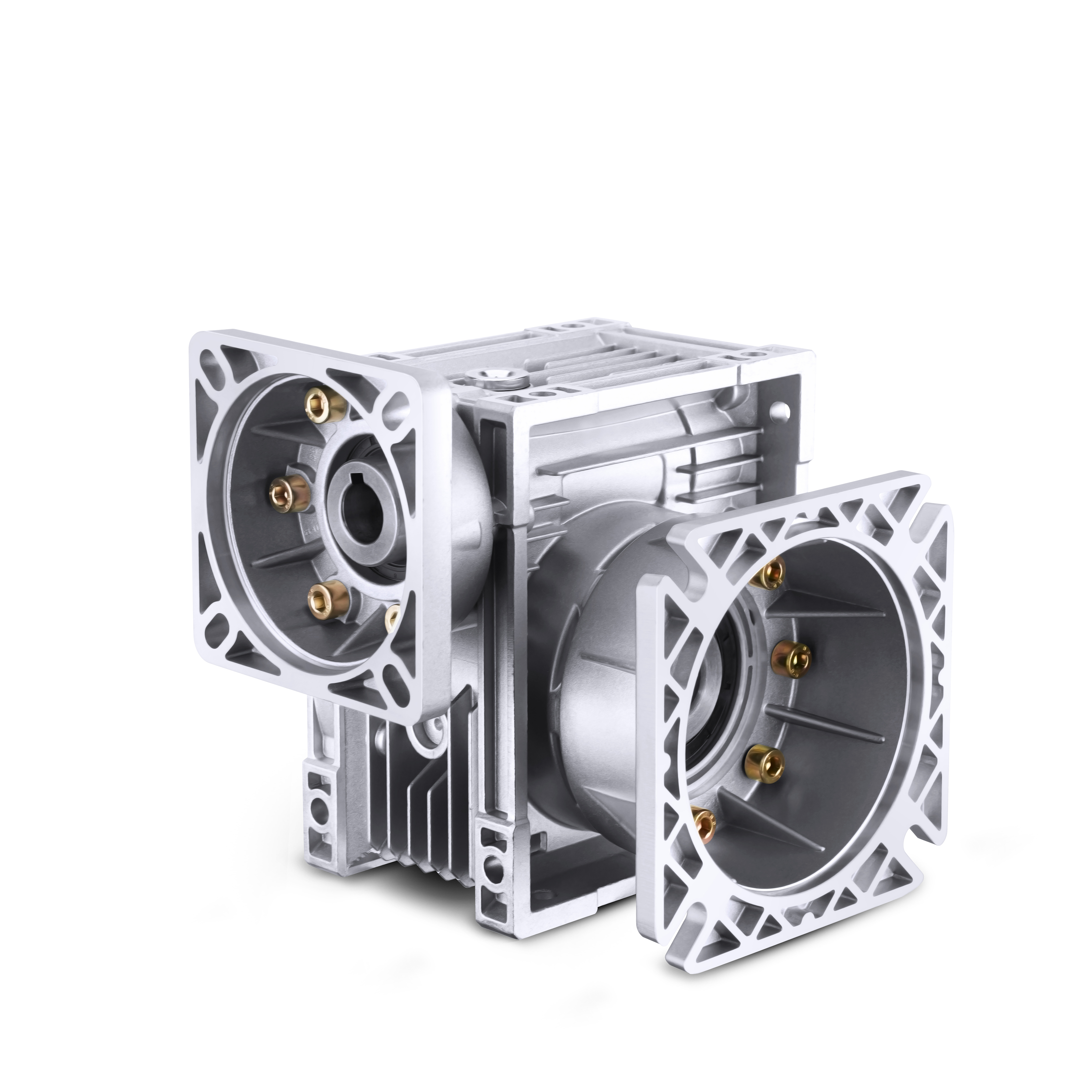

A compact, reliable gearmotor unit combining an NMRV series worm gear reducer with a high-efficiency electric motor. Designed for a wide range of industrial applications requiring high torque, low speed, and self-locking capabilities.

This NMRV worm gearmotor is engineered for stable right-angle power transmission, smooth operation, and easy integration. Ideal for conveyors, packaging lines, automation equipment, and general speed-reduction duties.

1. Core Performance Parameters

Key parameters and ranges for quick selection.

| Parameter | Value / Description |

|---|---|

| Model Series | Nmrv 040 / 050 / 063 / 075 / 090 |

| Gear Ratio Range | 5:1 to 100:1 (Standard ratios: 7.5–100:1) |

| Rated Output Torque | 3.2 N·m ~ 1190 N·m (Varies by model and ratio) |

| Applicable Motor Power | 0.09 kW ~ 7.5 kW (Common range) |

| Transmission Efficiency | 50% ~ 90% (Efficiency decreases with higher ratios) |

| Key Features | High gear ratio, smooth operation, self-locking function |

2. Mechanical Design & Materials

Core components and mounting interface.

Core Components

- Housing: Aluminum alloy (lightweight, good heat dissipation, corrosion resistant)

- Worm Wheel: Wear-resistant phosphor bronze (industry standard)

- Worm: Surface-hardened alloy steel (e.g., 20CrMnTi)

Interface & Mounting

- Output: Solid shaft output

- Input: IEC standard flange (B5 / B14)

- Mounting: Foot mounted

3. Mated Motor Specifications

Motor type and environment ratings.

Motor Type

- Type: Three-phase/single-phase asynchronous motor (IEC standard)

- Poles: Typically 4-pole (input speed ~1400–1500 RPM)

- Efficiency: Various efficiency classes available (IE1, IE2, IE3)

Protection & Environment

- IP Rating: IP55 (dust and water jet proof)

- Insulation Class: Class F (155°C)

- Ambient Temperature: -10°C to +40°C

4. Typical Application Areas

Common scenarios where this reducer is used.