About Us

Who We Are

Our Values

At ZPGear, we believe great gearboxes start with disciplined engineering and end with consistent results in the field. We hold ourselves to strict quality standards across design, manufacturing, and inspection—so every gearbox and gear reducer we deliver performs reliably and efficiently.

We stay close to real customer applications, turning feedback into practical improvements in our power transmission and motion control solutions. From pre-sales selection to after-sales service, our team provides responsive technical support to help partners reduce downtime, improve productivity, and build long-term confidence in ZPGear.

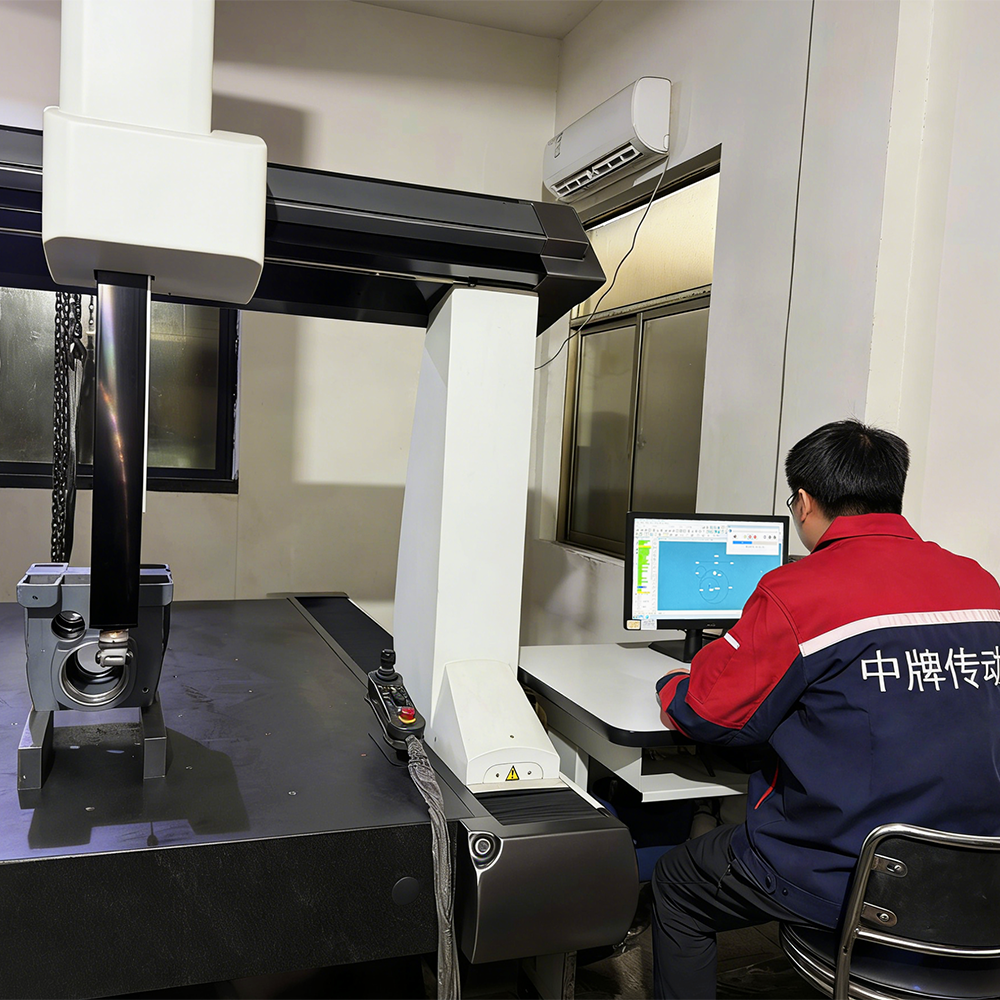

Our Commitment to Quality

ZPGear products are engineered with precision and manufactured using the latest technologies to ensure optimal performance and durability. We perform rigorous testing and quality control at every stage of production, ensuring that each gearbox delivers maximum efficiency and reliability for your applications.

Cast/forge housings and gear/shaft blanks; normalize or stress-relieve with heat-lot traceability; reserve finishing stock.

Establish unified datums via CNC; finish bearing seats, gear blanks, and critical fits to tight GD&T.

Carburize/nitride to specified hardness/case depth; geargrinding/honing with micro-corrections to meet ISO grade and low NVH.

Set bearing preload and backlash; apply seals andlubricant; pass no-load/loaded tests before shipment.

Certification