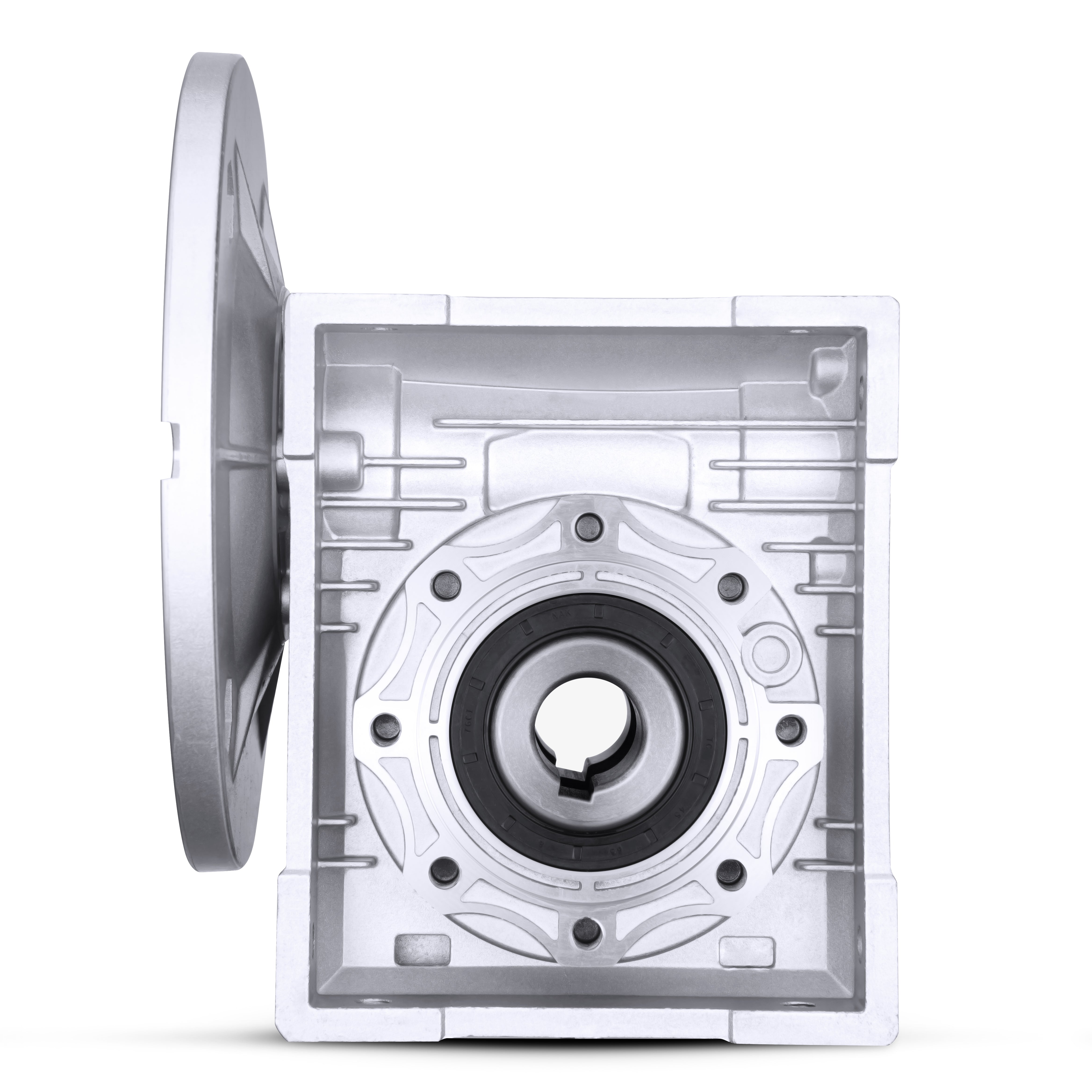

NMRV

Technical Specifications

NMRV Worm Gear Reducer delivers dependable high-torque reduction in a compact footprint. With flexible mounting options, wide ratio coverage, and easy motor coupling, it’s built for fast replacement and straightforward installation. ZPGear supports OEM/ODM customization for shaft size, flange, paint color, nameplate, and packaging—helping you match your equipment and shorten lead time.

Core Performance Parameters

Key operating range and performance data for quick comparison.

| Model Series | NMRV 030 / 040 / 050 / 063 / 075 / 090 / 110 / 130 / 150 |

|---|---|

| Gear Ratio Range | 5:1 to 100:1 (12 standard ratios, custom available) |

| Output Torque | 1.8 N·m ~ 500 N·m |

| Input Power | 0.06 kW ~ 15 kW |

| Efficiency | 60% ~ 90% (decreases with higher ratios) |

| Noise Level | < 65 dB (at 1 m distance) |

Mechanical Design & Materials

Materials, sealing, and interface options for durability and compatibility.

Core Components

- Worm: 20CrMnTi alloy steel, carburized & quenched (HRC58–62).

- Worm Wheel: ZCuSn10Pb1 tin bronze for superior wear resistance.

- Housing: ADC12 die-cast aluminum with cooling fins.

Seals & Interfaces

- Sealing: Double-lip oil seal + labyrinth structure (IP65 rated).

- Input: IEC/B5/B14 standard flange for motor compatibility.

- Output: Solid or hollow shaft options available.

Typical Application Scenarios

Common use cases where this gearbox is frequently applied.